Frequently Asked Questions

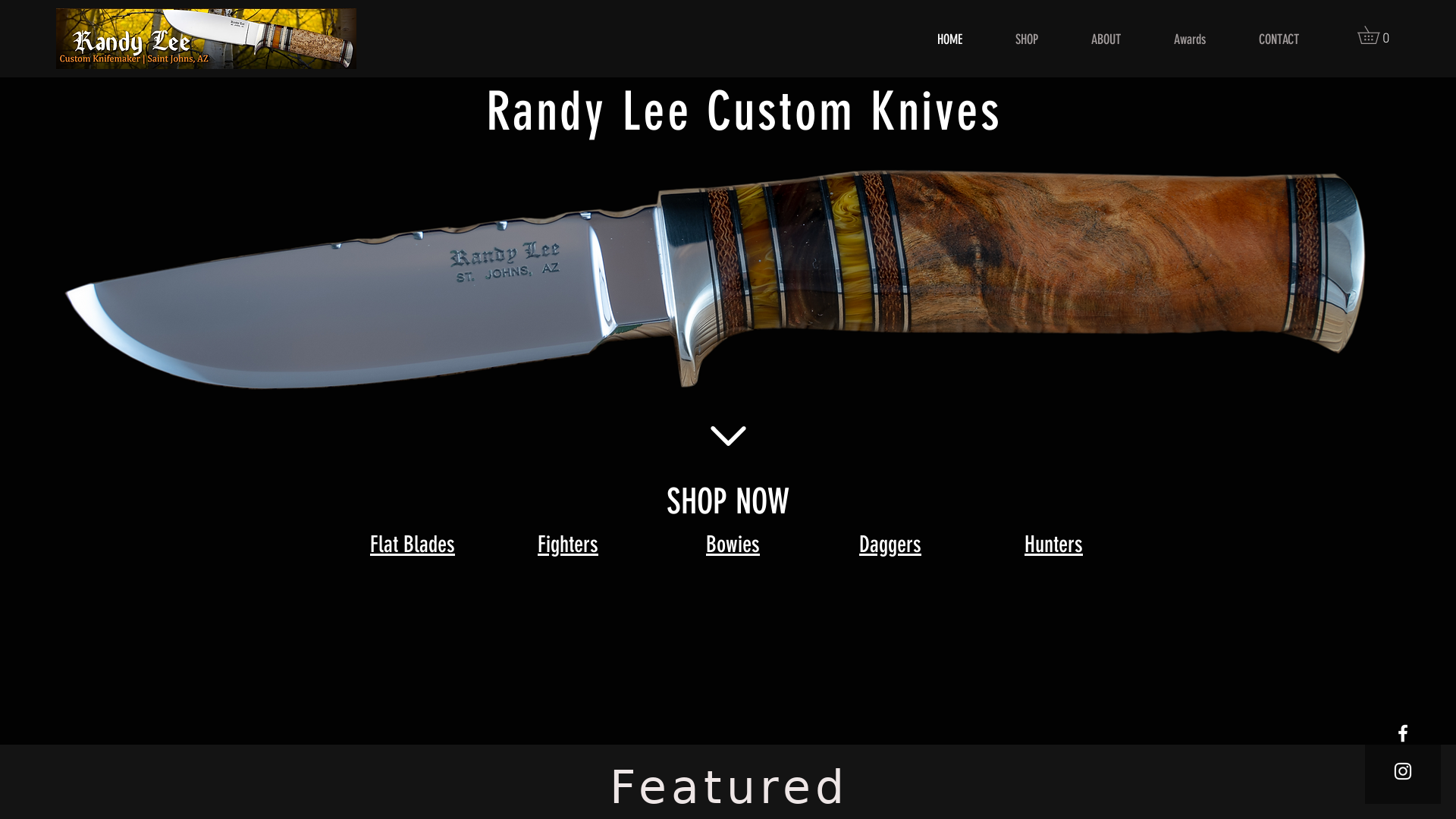

Custom knife makers offer a unique proposition in the cutlery market; they bring an unparalleled level of craftsmanship, individuality, and quality to their creations. Unlike mass-produced variants, a custom knife is a product of meticulous attention to detail and typically features superior materials. These handcrafted masterpieces are often hardier, sharper, and more durable; a testament to the skill and care invested in their creation. They also offer an aesthetic appeal that is seldom matched by manufactured knives, boasting unique designs and often personalised touches.

Purchasing a custom knife is not just about acquiring a tool, but it's also an investment in a piece of art. The passion of the knife maker, their expertise and their dedication to the craft is imbued in each piece they create. Therefore, a custom knife often holds more than just functional value; it carries an emotional significance and a story. So, if you value quality, longevity and the human touch in your cutlery, choosing a custom knife maker could be a wise decision. Remember, it's not merely a purchase, but an investment in a piece of enduring craftsmanship that can even become a cherished heirloom.

The timeline for crafting a custom knife can vary significantly; it's largely dependent on the complexity of the design and the craftsmanship involved. On average, a proficient custom knife maker may take anywhere from a few days to several weeks to complete a single piece. This is because the process involves intricate tasks such as selecting the appropriate material, forging the blade, honing the edge, and crafting the handle – all of which demand meticulous attention to detail and a significant investment of time.

However, it's essential to remember that the allure of custom knives lies not in their speed of production but in their unique character and superior quality. These handcrafted tools, shaped by skilled artisans, offer unparalleled functionality and aesthetic appeal that mass-produced knives often can't match. Therefore, when considering a custom knife, patience is key; the wait is typically rewarded with an exceptional tool that reflects the mastery of its maker and potentially, the personality of its owner.

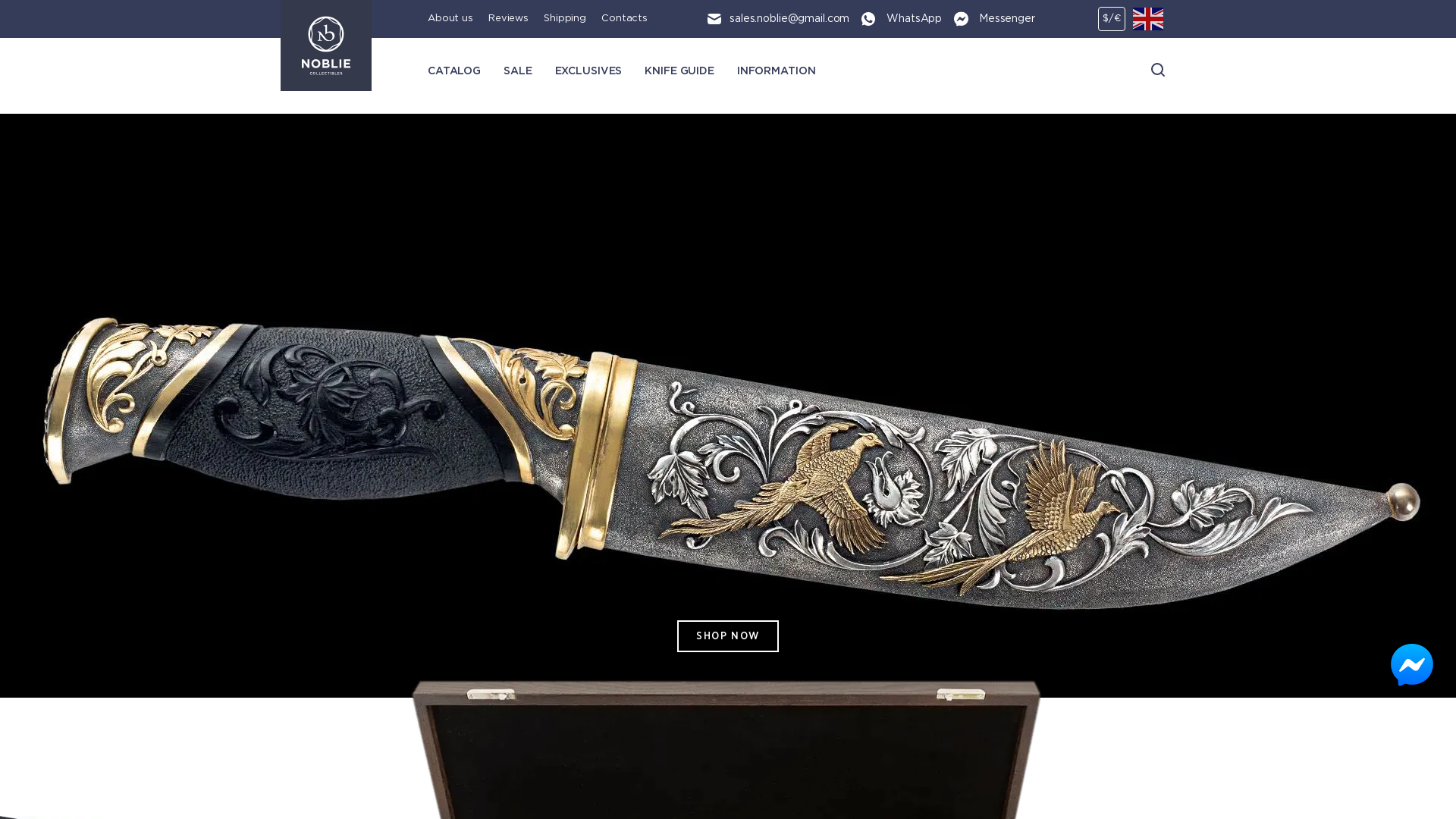

Custom knife makers, artisans in their own right, often utilize a diverse range of materials to create their unique and functional masterpieces. Predominantly, the blades are forged from high-quality steel variants; such as stainless steel, carbon steel, or Damascus steel, renowned for their durability and edge retention.

However, the blade is but half the story; the handle, also known as the 'tang', can be crafted from a medley of materials. From classic hardwoods and bone for a traditional aesthetic, to modern materials like carbon fiber and G-10 for a contemporary edge; the choice is as varied as it is personal.

Each material chosen impacts not just the overall look and feel of the knife, but also its performance and longevity. It's essential to consider the knife's intended use, whether that's for culinary prowess in the kitchen, or rugged resilience in the great outdoors, when deciding on the right custom knife maker.

With an abundance of options available, conducting thorough research and reading comprehensive reviews can help in making an informed decision. Ultimately, the artistry and craftsmanship of custom knife makers ensure a product that is not only practical, but also an embodiment of personal style and preference.

Indeed, custom knife makers often specialize in specific styles or designs, each honing their artistry to produce unique, high-quality blades. These specialties can range widely; from traditional Japanese Katana or Tanto blades, to rustic hunting knives, to modern tactical styles, to ornate collector’s pieces, and beyond. Some artisans may focus on creating replicas of historical pieces, while others may innovate with contemporary designs; the spectrum of custom knife making is broad and diverse.

When comparing options, you'll want to consider the maker's expertise in the style you're interested in. Look for a knife maker with a strong portfolio in your desired style, and consider their reputation within the community. Keep in mind, the materials used, the craftsmanship, and the level of customization will all impact the price. So, whether you’re searching for a functional tool, a piece of art, or a blend of both; finding the right custom knife maker is key to ensuring your knife will meet your exact needs and aesthetic preferences.

Custom knife makers craft pieces that often bear heftier price tags than their manufactured counterparts; a reflection of the labor-intensive, artisanal process behind their creation. Unlike mass-produced knives, custom pieces encapsulate the maker's unique artistry, expertise, and the premium materials used, all of which contribute to their higher cost. However, this doesn't necessarily mean that custom knives are always exorbitantly priced; the spectrum of costs is as diverse as the knife makers themselves, ranging from affordable hand-crafted pieces to high-end luxury items.

When comparing between custom and manufactured knives, it's essential to consider the value beyond the price tag. Custom knives, with their superior craftsmanship and personalized touch, offer a unique blend of functionality and aesthetics that can justify their higher cost. Remember, to make an informed decision, factor in not just the expense, but also the quality, durability, and personal significance of the knife.

SEO-optimized keywords: custom knife makers, cost, manufactured knives, price comparison, value, craftsmanship.

When embarking on the journey to select a custom knife maker, there are several salient factors you should consider; craftsmanship, materials used, and customer satisfaction are among the most critical.

High-quality custom knife makers are characterized by their exceptional craftsmanship; they meticulously handcraft each piece, ensuring it is not only aesthetically pleasing but also functional and durable.

Materials used play a significant role in determining the knife's longevity and performance; look for makers who utilize top-grade steel and handle materials.

Customer satisfaction is another barometer of a good knife maker; peruse reviews and testimonials to gauge if the maker consistently meets or surpasses customer expectations.

Be mindful of these points and you'll be able to cut through the clutter of choices and find a custom knife maker that truly sharpens your interest.

Absolutely; the beauty of collaborating with custom knife makers lies in the ability to infuse your personality and preferences into the design.

Custom knife makers, often artisans with a blend of technical skill and artistry, typically offer a wide range of personalization options; these may encompass the overall design, choice of materials, and intricate detailing such as engravings.

Therefore, whether you desire your initials, a meaningful symbol, or a complex pattern etched onto your knife, it's usually within the realm of possibility.

However, bear in mind that the extent of customization may vary between different knife makers; some may be more equipped than others to execute intricate designs or unique requests.

Therefore, it's crucial to discuss your ideas and expectations with the knife maker beforehand to ensure they can bring your vision to life.

Remember to read reviews, compare portfolios, and consider the expertise of various knife makers in your decision-making process; after all, a custom knife is not just a tool, but a personalized work of art.

Custom knife makers meticulously craft these unique pieces, fusing artistry with practicality; therefore, ensuring their longevity is paramount.

Your custom knife's maintenance largely hinges on proper cleaning, storage, and sharpening.

- Always clean your knife manually, eschewing dishwashers as they may corrode your knife's material.

- Use mild soap, warm water, and a soft cloth to gently cleanse the blade; ensure it's thoroughly dried before storage to avoid rusting.

Speaking of storage, consider investing in a knife block or magnetic strip; these provide a secure space, reducing accidental injuries and blade dulling.

Sharpening your knife is a delicate art; it's essential to maintain the cutting edge without compromising the blade's integrity.

This process varies with the type of blade; thus, it's advised to follow the custom knife maker's guidelines or consult a professional.

Furthermore, periodic oiling of the blade, especially for carbon steel knives, can help prevent rust and maintain the luster.

Remember, a custom knife is not just a tool, but a work of art; treating it with care will ensure it lasts for generations.

Through this careful upkeep, you can preserve the functionality and beauty of your custom knife, making it a treasured heirloom in your collection.

Absolutely; custom knife makers are skilled artisans who often specialize in crafting knives from a myriad of materials, including specific metals.

Whether you desire a robust carbon steel blade for its distinguished durability; or perhaps a sleek stainless steel knife for its corrosion resistance, custom knife makers are adept at materializing your specific needs.

They can even go the extra mile, utilizing exotic materials like Damascus steel or Mokume-gane, providing not only function but also an artistic flair to your custom knife.

However, it's important to remember that each material affects the knife's performance, maintenance, and cost differently; a balance between your preferences and practicality should be delicately negotiated.

Some custom knife makers may also have limited access to certain materials, so it's essential to discuss your requirements in detail with the maker.

In this realm of bespoke craftsmanship, researching and comparing between different custom knife makers will be key to achieving your perfect blade.

Finding reputable custom knife makers can be a thrilling quest; one that requires diligence and a keen sense for craftsmanship. It's about delving into an artisan's world, where every blade tells a story and each knife is a testament to the maker's skill and attention to detail.

Start by researching online; websites, forums, and social media platforms are teeming with information about custom knife makers. Look for makers with positive reviews, a history of reliable service, and a portfolio that showcases their expertise and creativity.

However, don't just stop at digital scrutiny; join local knife clubs or attend knife shows to interact with makers directly. This hands-on approach allows you to assess the quality of their work, understand their process, and discuss customization options. Always ask about the materials used, the heat treatment process for the blades, and their warranty policy. Remember, a reputable knife maker will be transparent about their practices and stand behind their products.

SEO terms to consider include "custom knife maker," "handmade knives," "knife artistry," "blade craftsmanship," and "customized knives."

Indeed; custom knife makers, the skilled artisans that they are, have the capability to replicate a knife you've seen elsewhere. However, it's important to note that each maker possesses their unique style and techniques; hence, while the replicated design may bear close resemblance, it may not be an exact clone. The beauty of custom knife making lies in its individuality; the subtle variations in each piece, reflecting the maker's craftsmanship.

When seeking replication, ensure you respect copyright laws; some designs are protected, prohibiting replication. Also, remember that the artistry, quality of materials, and time invested can make custom knives more expensive than their mass-produced counterparts. So, while a custom knife maker can likely recreate a design you admire, the end product will invariably possess its own unique charm, embodying the creator's personal touch.

Custom knife makers are celebrated for their attention to detail; they meticulously forge each piece with precision and handcraftsmanship, often resulting in a product that outlives its mass-produced counterparts.

Unlike assembly-line creations, custom knives are born from a meticulous process of selecting high-quality materials, careful shaping, and precise heat-treatment. This makes them not only aesthetically superior, but also often more durable, capable of withstanding the rigors of daily use with minimal wear and tear.

However, it's important to note that not all custom knives are created equal; the durability largely depends on the maker's skill and the quality of materials used. Therefore, when deciding between custom and mass-produced knives, consider factors such as the maker's reputation, the source and grade of the materials, and the specific crafting process employed.

With a well-chosen custom knife, you can expect a level of durability and performance that is difficult, if not impossible, to find in mass-produced options.